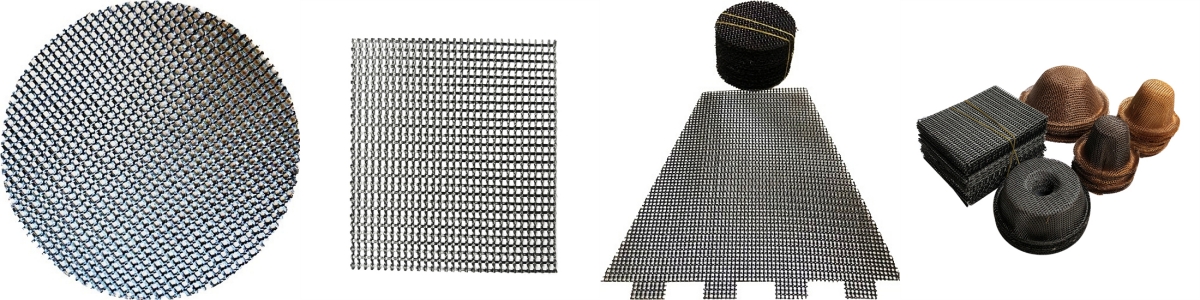

How to use fiberglass filtration mesh for metal casting

In cast iron, aluminum, steel castings, the slag contained in the metal solution is not easy to clean, it will cause slag holes, pores and other defects and waste, so how to use the casting filter mesh?

The filter mesh can be cut into any specification, placed on the sprue parting surface of the box pressing, such as the combination of filter net and slag bag, its effect will be better.

1. Use area of filter net:

The relationship between the cross-sectional area F1 of the casting system and the original cross-sectional area F2 of the casting system without putting the filter net can be expressed as follows:

F1 = F2 / AxB;

A: the porosity of the filter screen, generally 50-60%.

B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

2. Position of filter screen:

Related links:What Are Wear Plates Used For?

What To Consider When Choosing Business Trash Cans

A. Place the filter under the sprue cup;

B. Placed on the parting surface under the sprue;

C. Three different positions on the lap surface of the runner.

3. Precautions for use of filter screen:

When the filter is used, it is necessary to guard against oblique pulling, wear and break. The size of the filter block should be greater than the size of the gate area 20-30mm. Handling, handling should be careful to handle, prevent extrusion, moisture.

Casting filter screen for metal solution filtration purification treatment, remove the slag and part of the gas in the metal solution, improve its quality, reduce the scrap rate of high-quality products. It not only brings objective economic benefits to the majority of producers but also reduces energy consumption, improves labor productivity and product quality.

For more information about filters, please leave us a message, we will reply you as quickly as possible!

10 Frequently Asked Questions About PC Wire

Sintered Porous Metal Stainless Steel Discs: Versatile and Reliable

Pipe Inner Surface Hardfacing Cladding Machine: Enhancing Durability and Performance

787

0

0

Related Articles

-

1096

0

0

-

1079

0

0

Comments

All Comments (0)