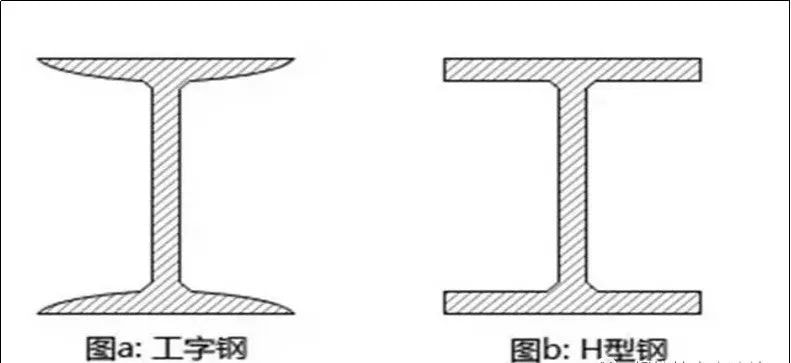

Can't Tell the Difference Between I-Beam and H-Beam?

May. 15, 2024

People often wonder about the difference between I-beams and H-beams due to their similar shapes. How should one choose between them for practical applications? Even seasoned construction professionals sometimes struggle to explain the distinctions clearly.

Here's a detailed explanation: Many mistakenly believe that the I-beam is a domestic term and the H-beam is a foreign name. In truth, I-beams and H-beams differ significantly in shape.

I-beam

I-beams are primarily categorized into ordinary I-beams, light I-beams, and wide-flange I-beams. Based on the height ratio of flange to web, they are classified into wide, medium, and narrow wide flange I-beams. The first two types come in sizes ranging from 10 to 60, corresponding to a height of 10 to 60 cm.

At the same height, light I-beams have narrow flanges, thin webs, and are lightweight. Wide-flange I-beams, also known as H-beams, have parallel legs with no slope on the inside, making them economical section steel. These beams are rolled on four-roll universal rolling mills, earning the name "universal I-beams." Ordinary I-beams and light I-beams follow national standards.

An I-beam is characterized by its "I"-shaped cross-section. The inner surfaces of the upper and lower flanges are sloped, typically at a 1:6 ratio, making the flanges thin on the outside and thick on the inside. This design leads to inconsistencies in the cross-sectional properties of the main planes, complicating the utilization of strength properties in applications.

Although thicker I-beams are available, the structural design of I-beams limits their torsion resistance capabilities.

H-beam

H-shaped steel boasts an economical cross-section and high efficiency, with an optimized cross-sectional area distribution and a more favorable strength-to-weight ratio. Its cross-section mirrors the shape of the letter "H."

Since all parts of H-shaped steel are arranged at right angles, it offers strong bending resistance in all directions, simplifies construction, saves costs, and reduces structural weight. Consequently, H-beams are widely used.

H-beams parades significant differences from I-beams, primarily in their flange designs and their consistently parallel upper and lower surfaces.

The cross-sectional properties of H-beams far surpass those of traditional I-beams, channel steel, and angle steel.

With straight outer edges and no inner slope, H-beams simplify welding and splicing. They also offer better mechanical properties per unit of weight and save on materials and construction time.

While I-beams can handle direct pressure and tension well, their narrow wing plates limit their resistance to torsion. H-beams, on the other hand, offer a balanced strength profile, though each type has its specific advantages and limitations.

Differences and Usage Instructions Between H-beam and I-beam

1. Whether ordinary or light, the I-beam's high and narrow cross-section results in significantly different moments of inertia along its main axes. Thus, it is generally used directly on its web plane or formed into lattice-type stress-bearing members.

I-beams are unsuitable for axial compression members or members perpendicular to the web plane and bent, limiting their application range.

2. H-beams are efficient and economical cross-section profiles. Their reasonable cross-sectional shape maximizes steel efficiency and enhances cutting capacity.

Unlike ordinary I-beams, H-beams feature widened flanges, with inner and outer surfaces usually parallel, allowing for easy connections using high-strength bolts. Their size constitutes a reasonable series with complete models, facilitating easier design and selection (excluding I-beams for crane beams).

3. The flanges of H-shaped steel are consistently thick, encompassing rolled sections and combined sections made from welded plates. In contrast, I-beams are rolled sections with an inner flange edge slope of 1:10 due to production limitations.

Rolling H-shaped steel differs from rolling ordinary I-beams, which only use horizontal rollers. Given the flange's width and minimal slope, an additional set of vertical rollers is required, complicating the rolling process and equipment compared to standard rolling mills.

In China, the maximum height for rolled H-shaped steel is 800mm. Heights exceeding this must be welded and combined.

4. I-beams, with their small side lengths and large heights, withstand force in only one direction.

5. The deep and thick channel of H-shaped steel can bear force in both directions.

6. As steel structure buildings develop, relying solely on I-beams is inadvisable. Thickened I-beams used as load-bearing columns may easily become unstable.

7. I-beams are suitable for beams, whereas H-beams can serve as load-bearing columns in structures.

8. H-shaped steel is an economical section steel with superior mechanical properties compared to I-beams. It is named after its "H"-shaped cross-section. Hot-rolled H-beam flanges are wider than those of I-beams, offer greater lateral stiffness, and stronger bending resistance. H-shaped steel is lighter than I-shaped steel for the same specifications.

9. The flange of I-shaped steel features a variable cross-section, thick at the web and thin on the outside. In contrast, the flange of H-shaped steel has a constant cross-section.

10. HW, HM, and HN are general names for H-shaped steel. H-shaped steel is welded, whereas HW, HM, and HN are hot-rolled.

11. HW refers to H-shaped steel with heights and flange widths that are almost equal. It is mainly used for steel core columns in reinforced concrete frame structures, also known as stiff steel columns, primarily serving as columns in steel structures.

12. HM describes H-shaped steel with a height-to-flange width ratio of approximately 1.33 to 1.75. It is chiefly used in steel structures, functioning as steel frame columns and frame beams in load-bearing frames, such as device platforms.

13. HN signifies H-shaped steel with a height-to-flange width ratio of 2 or more, mainly used for beams. The use of I-shaped steel is comparable to that of HN-shaped steel.

553

0

0

None

None

Comments

All Comments (0)